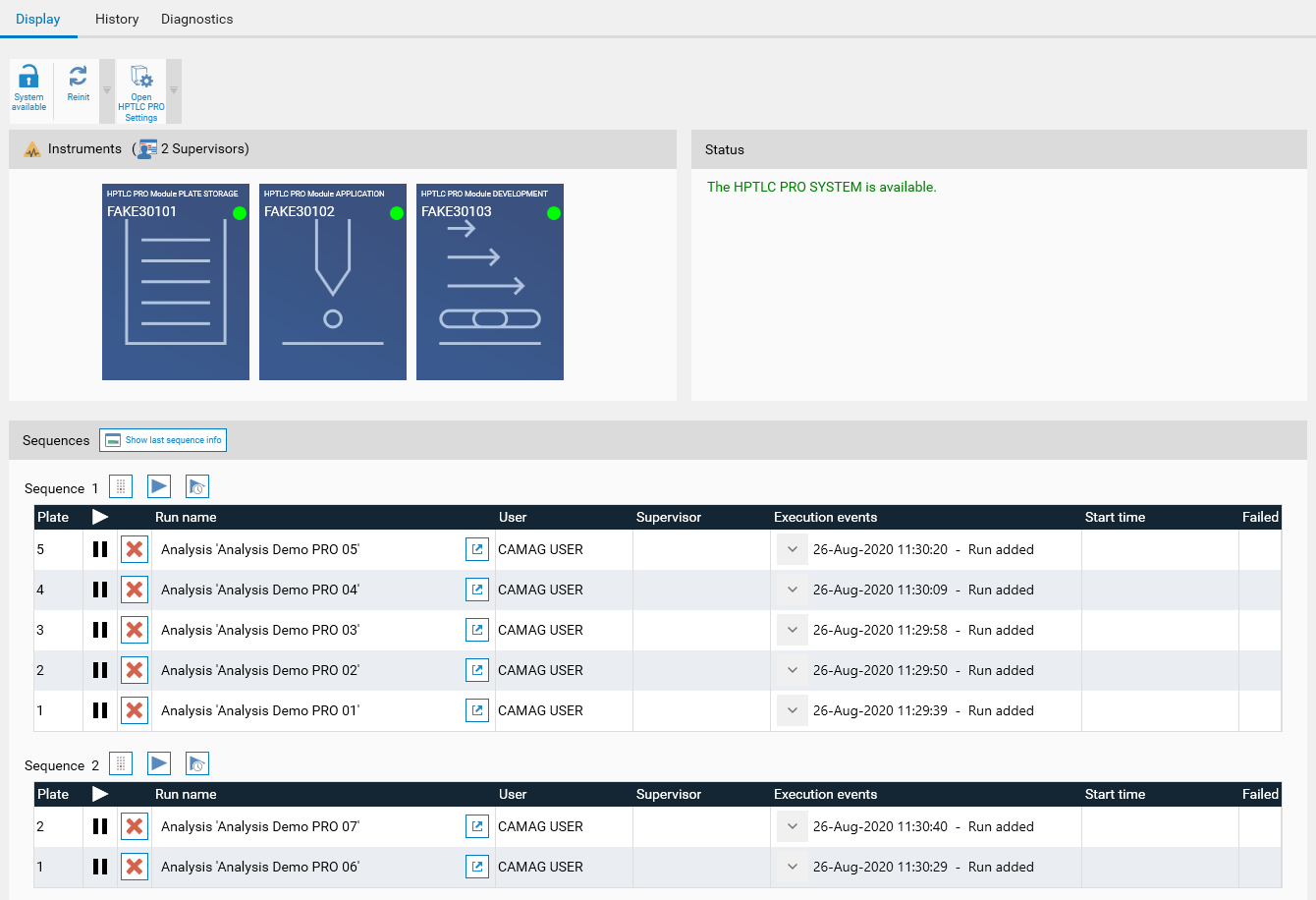

Display Tab overview¶

The Display tab shows the current status of the CAMAG® HPTLC PRO SYSTEM. More detailed than the New HPTLC PRO SYSTEM Configuration window, it is though limited to a single HPTLC PRO SYSTEM and displays the runs information.

Toolbar¶

Lock/unlock each HPTLC PRO SYSTEM manually.

Lock/unlock each HPTLC PRO SYSTEM manually. The HPTLC PRO SYSTEM will reinitialize, useful after an external change (like removing a carrier). See Understanding the HPTLC PRO Module and HPTLC PRO SYSTEM initialization

The HPTLC PRO SYSTEM will reinitialize, useful after an external change (like removing a carrier). See Understanding the HPTLC PRO Module and HPTLC PRO SYSTEM initialization Open the HPTLC PRO SYSTEM Configuration view

Open the HPTLC PRO SYSTEM Configuration view

Modules¶

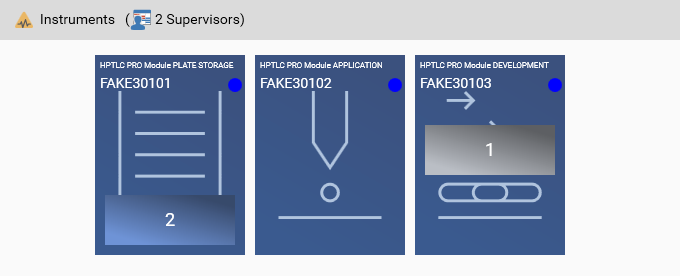

In addition to the display of the HPTLC PRO Module statuses, a schematic view of the carriers is displayed on the HPTLC PRO SYSTEM.

In the previous capture, one run was in progress on the second module and another run had its carrier on the conveyor of the first module. The carrier is here identified by a corresponding color and number in the runs sequence.

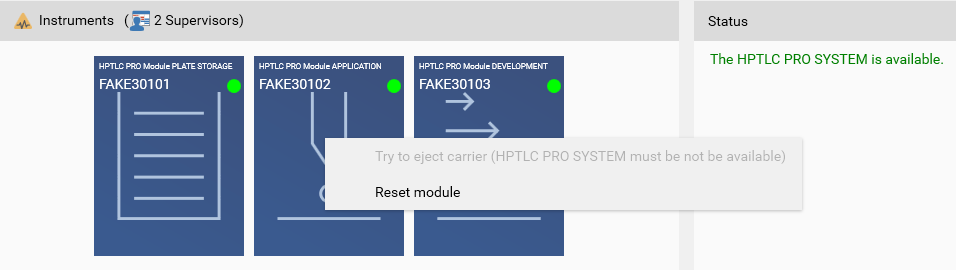

By right-clicking on the module:

once the HPTLC PRO SYSTEM is locked, the carrier can be manually ejected by using the Try to eject carrier function. If a HPTLC PRO Module PLATE STORAGE is present, the carrier is just placed on the conveyor and the user will have to open the door of the concerned HPTLC PRO Module to remove the carrier. Otherwise the carrier is moved to the manual unloading position of the last module of the HPTLC PRO SYSTEM and the user will have to unload it manually. This may be necessary after a reset, as the run was aborted but the carrier remains in the HPTLC PRO SYSTEM: the Conveyor Manager signals it as unexpected.

the Reset module feature can be interesting in case of a critical error received from the module. If the module was performing a step of a given run while hitting the Reset module entry, the run is aborted but the other runs on the HPTLC PRO SYSTEM can be recovered, while a reset of the HPTLC PRO SYSTEM causes the abort of all current runs.

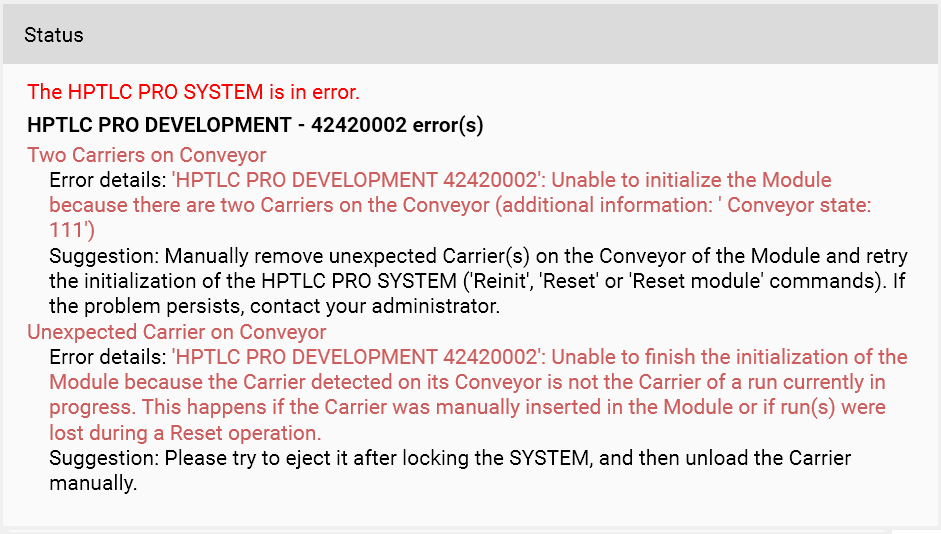

Status¶

The status of the HPTLC PRO SYSTEM and any HPTLC PRO Module’s error are display here. Each error is associated with details including contextual information and suggestions on how to resolve the error. For example in the previous capture, two carriers were manually placed on the conveyor of the HPTLC PRO Module DEVELOPMENT and an initialization tentative was made by hitting the Reinit button.

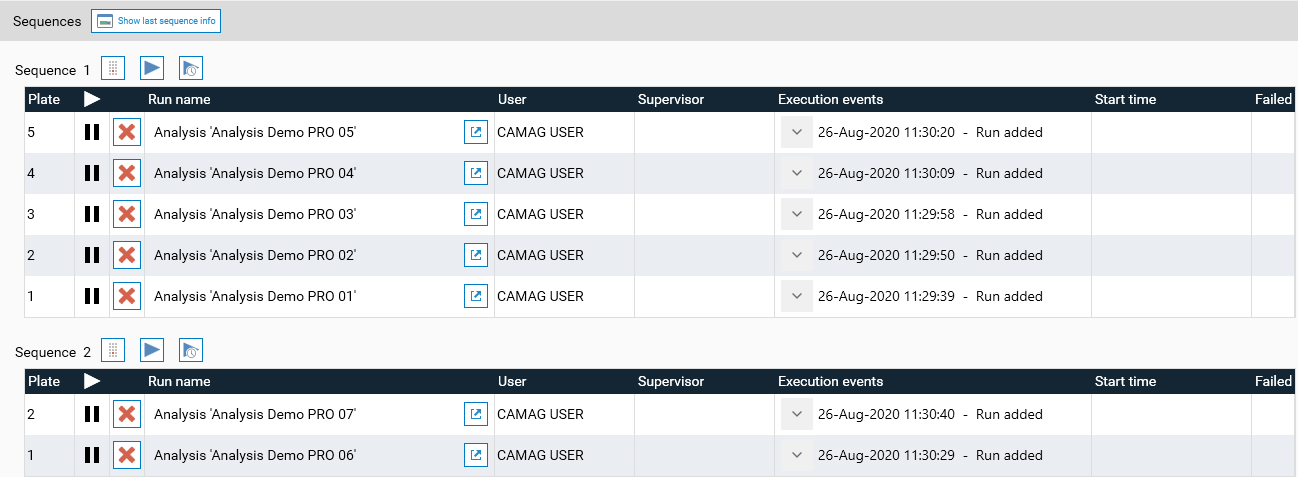

Sequences¶

All the runs are grouped into sequences of this HPTLC PRO SYSTEM. Hit the  button to display the last executed sequence information (see Last sequence info).

For each sequence, the user can:

button to display the last executed sequence information (see Last sequence info).

For each sequence, the user can:

See the rack configuration of this sequence.

See the rack configuration of this sequence. Execute the sequence. See Execution of a sequence

Execute the sequence. See Execution of a sequence Execute the sequence at a specific time. See Execution of a sequence

Execute the sequence at a specific time. See Execution of a sequence

Note

A sequence can contain up to 5 runs.

The different columns give more information about each run.

Plate: a number to identify the order (and the corresponding row in the stacker if a CAMAG® HPTLC PRO Module PLATE STORAGE is used) and a color code to help identify the plate/carrier in the Instruments view above (automatically generated)

Running status: either running or not

Important

A run is marked as running as soon as the sequence execution has started.

Abort the run (only possible if the sequence is not running, otherwise must be done from the analysis.)

Abort the run (only possible if the sequence is not running, otherwise must be done from the analysis.)Run name: name of the corresponding analysis. The link will open the analysis

User: which visionCATS user added the run to the sequence

Supervisor: which visionCATS user executed the sequence and will be notified

Execution events: like in the Chromatography tab of the analysis during the execution of the run, the full list of execution events is displayed

Start time: when the run was selected for execution

Failed: display runs having an unrecoverable error (for example if a carrier is blocked during a movement on a conveyor). Failed runs are removed from the HPTLC PRO SYSTEM the next time it is initialized (for example by reenabling it or by using the Reset function)

Note

The view can also display the requested consumables when the sequence execution is started (see Consumables check).